Orodha ya maudhui:

- Mwandishi John Day day@howwhatproduce.com.

- Public 2024-01-30 12:51.

- Mwisho uliobadilishwa 2025-01-23 15:11.

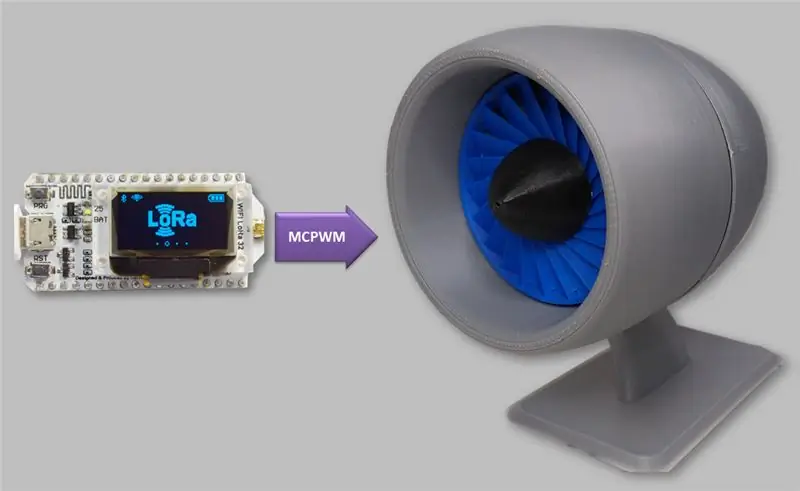

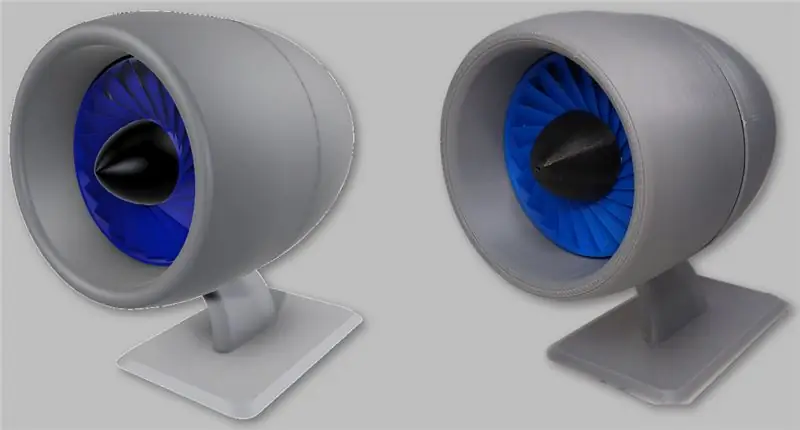

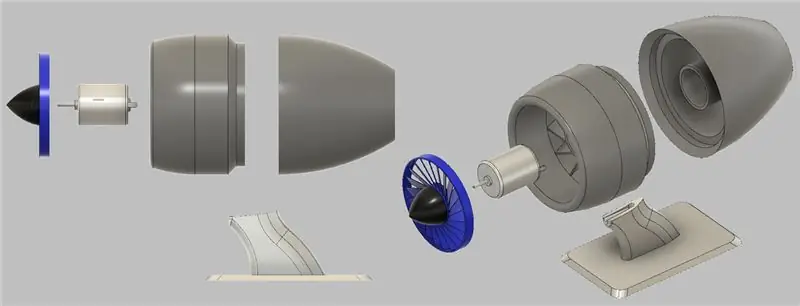

Leo, nitazungumzia turbine ya umeme na ESP32. Mkutano una sehemu ambayo ilichapishwa kwa 3D. Nitawasilisha kazi ya PWM ya ESP32 ambayo inafaa kudhibiti motors za umeme. Hii itatumika katika motor DC. Nitaonyesha pia utendaji wa hii MCPWM (Motor Control PWM) katika maombi ya vitendo.

Nilitumia ESP32 LoRa katika mradi huu, na nadhani ni muhimu kutambua hapa kwamba microcontroller hii ina vizuizi viwili ndani yake. Vitalu hivi vina uwezo wa kudhibiti motors tatu kila moja. Kwa hivyo, inawezekana kudhibiti hadi motors sita na PWM, zote kwa kujitegemea. Hii inamaanisha kuwa udhibiti nitakaotumia hapa sio kiwango (ambacho ni sawa na Arduino). Badala yake, udhibiti ni chip yenyewe, ambayo inahakikishia ESP32 kubadilika sana kwa heshima na udhibiti wa magari.

Hatua ya 1: Maonyesho

Hatua ya 2: Udhibiti wa Magari ya PWM

Mchoro Mkuu:

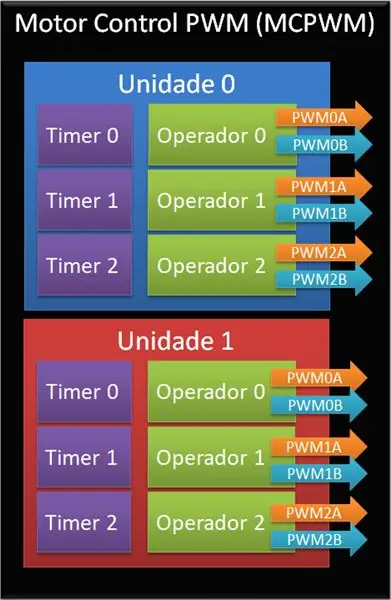

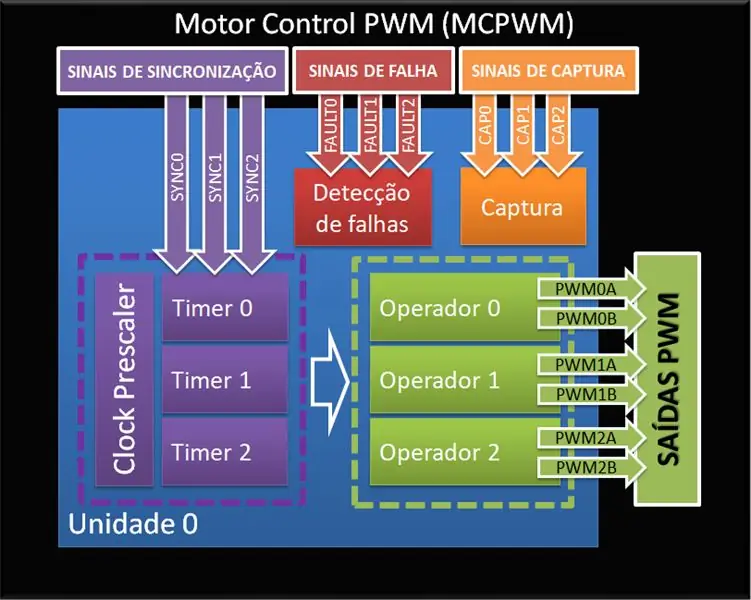

Kazi ya MCPWM ya ESP32 inaweza kutumika kudhibiti aina anuwai ya motors za umeme. Ina vitengo viwili.

• Kila kitengo kina jozi tatu za PWM.

• Kila pato la A / B linaweza kusawazishwa na moja ya vipima muda vya maingiliano 0, 1, au 2.

• Timer moja inaweza kutumika kulandanisha zaidi ya jozi moja ya pato ya PWM

Mchoro Kamili:

• Kila kitengo pia kina uwezo wa kukusanya ishara za kuingiza kama DALILI ZA KUSAINISHA;

• Tambua DALILI ZA KOSA kwa overvur Voltage au motor;

• Pata maoni na SIGNALI ZA KUTEKA, kama vile nafasi ya Injini

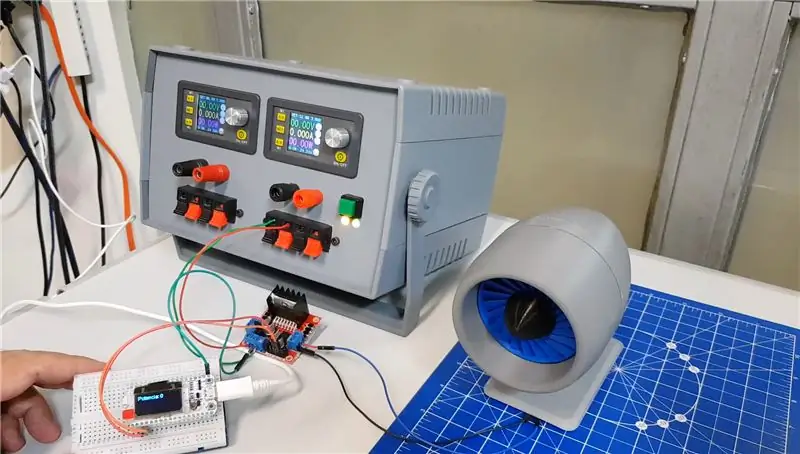

Hatua ya 3: Rasilimali Zilizotumiwa

• Rukia kwa unganisho

• Heltec Wifi LoRa 32

• Dereva wa kawaida wa DC

• Daraja H - L298N

• kebo ya USB

• Kitabu cha ulinzi

• Ugavi wa umeme

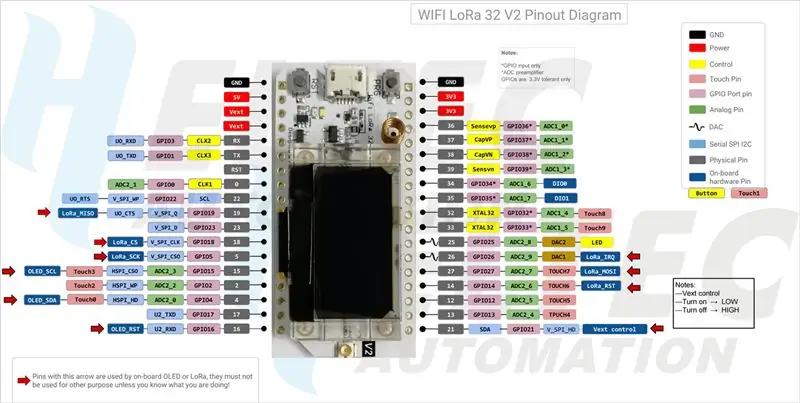

Hatua ya 4: ESP 32 Dev Kit - Pinout

Hatua ya 5: Upandaji wa Turbine

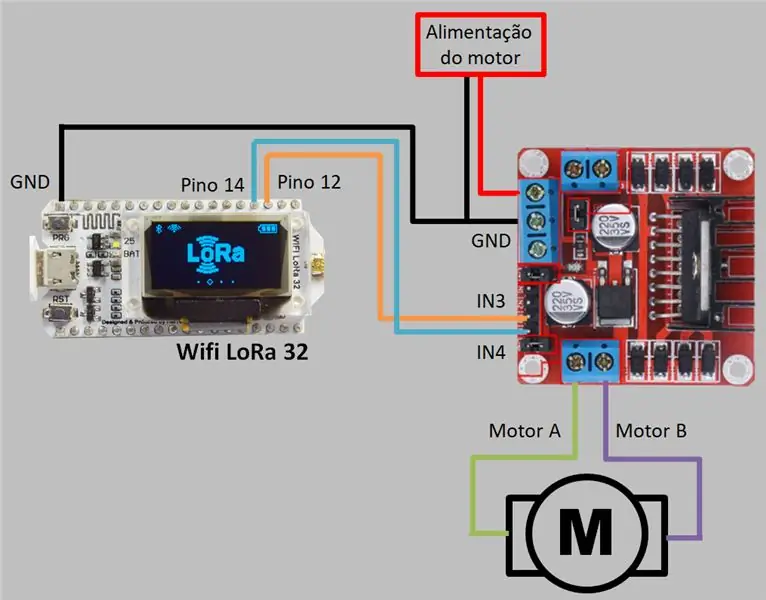

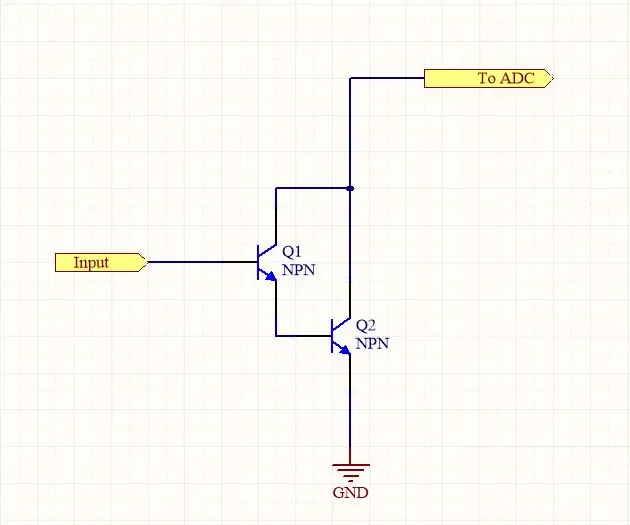

Hatua ya 6: Mzunguko - Uunganisho

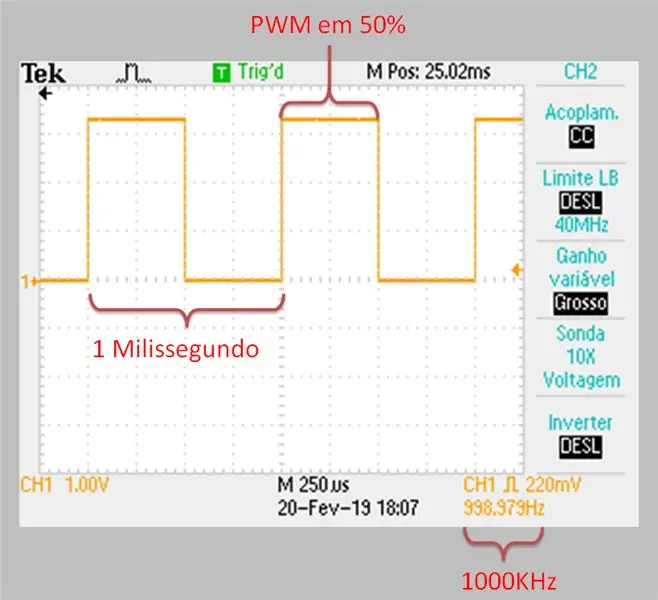

Hatua ya 7: Upimaji juu ya Oscilloscope

Hatua ya 8: Nambari ya Chanzo

Kichwa

#pamoja // Não é needário caso use Arduino IDE # include "driver / mcpwm.h" // inclui a biblioteca "Motor Control PWM" nativa do ESP32 #include // Necessário apenas para o Arduino 1.6.5 e posterior #include " SSD1306.h "// o mesmo que # pamoja na" SSD1306Wire.h "// OLED_SDA - GPIO4 // OLED_SCL - GPIO15 // OLED_RST - GPIO16 #fafanua SDA 4 #fafanua SCL 15 #fafanua RST 16 SSD1306 onyesho (0x3cc, SDA, SCL, RST); // Instanciando e ajustando os pinos do objeto "display" #fasili GPIO_PWM0A_OUT 12 // Declara GPIO 12 como PWM0A #define GPIO_PWM0B_OUT 14 // Declara GPIO 14 como PWM0B

Sanidi

kuanzisha batili () {Serial.begin (115200); onyesha.init (); //display.flipScreenVertically (); // Vira onyesho la wima la kuonyesha. Wazi (); // ajusta o alinhamento kwa onyesho la esquerda.setTextAlignment (TEXT_ALIGN_LEFT); // ajusta font kwa kuonyesha Arial 16.setFont (ArialMT_Plain_16); // mcpwm_gpio_init (unidade PWM 0, saida A, porta GPIO) => Instancia o MCPWM0A hakuna pino GPIO_PWM0A_OUT declarado no começo do código mcpwm_gpio_init (MCPWM_UNIT_0, MCPWM0A, GPIO_0A, GPIO_0A, GPIO_0A, GPIO_0A, GPIO_0A; GPIO_0A; // mcpwm_gpio_init (unidade PWM 0, saida B, porta GPIO) => Instancia o MCPWM0B hakuna pino GPIO_PWM0B_OUT declarado no começo do código mcpwm_gpio_init (MCPWM_UNIT_0, MCPWM0B, GPIO_P0) mcpwm_config_t pwm_config; pwm_config.frequency = 1000; // frequencyência = 500Hz, pwm_config.cmpr_a = 0; // Ciclo de trabalho (mzunguko wa ushuru) fanya PWMxA = 0 pwm_config.cmpr_b = 0; // Ciclo de trabalho (mzunguko wa ushuru) fanya PWMxb = 0 pwm_config.counter_mode = MCPWM_UP_COUNTER; // Para MCPWM assimetrico pwm_config.duty_mode = MCPWM_DUTY_MODE_0; // Fafanua ciclo de trabalho em nível alto // Inicia (Unidade 0, Timer 0, Config PWM) mcpwm_init (MCPWM_UNIT_0, MCPWM_TIMER_0, & pwm_config); // Fafanua PWM0A & PWM0B com kama mipangilio ya acima}

Kazi

// Função que usanidi wa opareta ya MCPWM A (Unidade, Timer, Porcentagem (ciclo de trabalho)) tuli tuli brushed_motor_forward (mcpwm_unit_t mcpwm_num, mcpwm_timer_t timer_num, float duty_cycle) {// mcpw (0, 1 ou 2), Operador (A ou B)); => Desliga o sinal do MCPWM no Operador B (Define o sinal em Baixo) mcpwm_set_signal_low (mcpwm_num, timer_num, MCPWM_OPR_B); // mcpwm_set_duty (unidade PWM (0 ou 1), Número do timer (0, 1 ou 2), Operador (A ou B), Ciclo de trabalho (% fanya PWM)); => Usanidi programu ya kufanya PWM hakuna Operador A (Ciclo de trabalho) mcpwm_set_duty (mcpwm_num, timer_num, MCPWM_OPR_A, duty_cycle); // mcpwm_set_duty_tyoe (unidade PWM (0 ou 1), Número do timer (0, 1 ou 2), Operador (A ou B), Nível do ciclo de trabalho (alto ou baixo)); => fafanua aina nyingine ya maandishi (alto ou baixo) mcpwm_set_duty_type (mcpwm_num, timer_num, MCPWM_OPR_A, MCPWM_DUTY_MODE_0); // Nota: Chame essa função toda vez que for chamado "mcpwm_set_signal_low" ou "mcpwm_set_signal_high" para manter o ciclo de trabalho configurado anteriormente} // Função que configura o MCPWM Do operador B (Unidade, Timer, Porcentagem) tuli tuli iliyosafirishwa_motor_ya nyuma (mcpwm_unit_t mcpwm_num, mcpwm_timer_t timer_num, float duty_cycle) {mcpwm_set_signal_low (mcpwm_num, timer_num, MCPWM_OPR_A); // Desliga o sinal do MCPWM no Operador A (Define o sinal em Baixo) mcpwm_set_duty (mcpwm_num, timer_num, MCPWM_OPR_B, duty_cycle); // Kusanidi porcentagem kufanya PWM hakuna Operador B (Ciclo de trabalho) mcpwm_set_duty_type (mcpwm_num, timer_num, MCPWM_OPR_B, MCPWM_DUTY_MODE_0); // kufafanua o Nivel kufanya Ciclo de Trabalho (alto ou Baixo)} // Função que para o MCPWM de ambos os Operadores tuli utupu brushed_motor_stop (mcpwm_unit_t mcpwm_num, mcpwm_timer_t timer_num) {mcpwm_set_signal_low (mcpwm_num, timer_num, MCPWM_OPR_A); // Desliga o sinal do MCPWM no Operador A mcpwm_set_signal_low (mcpwm_num, timer_num, MCPWM_OPR_B); // Desliga o sinal do MCPWM no Operador B}

Kitanzi

kitanzi batili () {// Hamisha o motor hakuna sentido horário brushed_motor_forward (MCPWM_UNIT_0, MCPWM_TIMER_0, 50.0); oled ("50"); kuchelewa (2000); // Para o motor brushed_motor_stop (MCPWM_UNIT_0, MCPWM_TIMER_0); oled ("0"); kuchelewa (2000); // Sogeza o motor hakuna sentido antihorário brushed_motor_backward (MCPWM_UNIT_0, MCPWM_TIMER_0, 25.0); oled ("25"); kuchelewa (2000); // Para o motor brushed_motor_stop (MCPWM_UNIT_0, MCPWM_TIMER_0); oled ("0"); kuchelewa (2000); // Aceleracao i de 1 a 100 kwa (int i = 10; i <= 100; i ++) {brushed_motor_forward (MCPWM_UNIT_0, MCPWM_TIMER_0, i); oled (Kamba (i)); kuchelewesha (200); } // Desaceleração i de 100 kuchelewa 1 (5000); kwa (int i = 100; i> = 10; i -) {brushed_motor_forward (MCPWM_UNIT_0, MCPWM_TIMER_0, i); oled (Kamba (i)); kuchelewesha (100); } kuchelewa (5000); }

Hatua ya 9: Pakua faili

INO

Kuchora

Ilipendekeza:

Gitaa ya Sanduku la Umeme la Umeme: Hatua 18 (na Picha)

Gitaa ya Sanduku la Umeme wa Umeme: Ingawa utengenezaji wa gita umetoka mbali katika miaka mia moja iliyopita, kuna historia ndefu kuonyesha kwamba hauitaji mengi kutengeneza gita. Unachohitaji tu ni kisanduku ili kupaza sauti, ubao wa kufanya kama fretboard, screws chache

Mshumaa-Umeme Mshumaa Umeme: Hatua 8 (na Picha)

Mshumaa wa Umeme wa Mshumaa: Baada ya kuona ripoti za habari juu ya Kimbunga Sandy na kusikia shida ambayo familia yangu yote na marafiki huko New York na New Jersey walipitia, ilinifanya nifikirie juu ya utayari wangu wa dharura. San Francisco - baada ya yote - inakaa juu ya wengine sana

Turbine iliyoboreshwa ya Umeme iliyotengenezwa kutoka kwa Zinazoweza kusindika tena: Hatua 16 (na Picha)

Turbine iliyoboreshwa ya Umeme iliyotengenezwa kutoka kwa vitu vinavyoweza kusindika tena: Hii ni turbine iliyojengwa kabisa, yenye umeme (EST) ambayo inabadilisha umeme wa moja kwa moja wa sasa (HVDC) kuwa kasi kubwa, mwendo wa rotary. Mradi wangu uliongozwa na Jefimenko Corona Motor ambayo inaendeshwa na umeme kutoka anga

Vipepeo vya umeme vya moto / umeme wa umeme: 4 Hatua

No-solder Fireflies / Bugs Lightning: Nilitaka kuongeza nzi za LED (mende wa umeme ambapo nilikulia) kwenye uwanja wangu kwa Halloween, na nikaamua kutengeneza zingine na nyuzi za LED na Arduino. Kuna miradi mingi kama hii, lakini nyingi zinahitaji kuuza na kuzungusha. Hizo ni nzuri, lakini mimi d

Umeme wa Umeme Kupima Msingi Mfumo wa Taa ya Umeme: Hatua 8

Umeme wa Umeme Kupima Msingi wa Taa ya Umeme: Je! Umewahi kufikiria kutengeneza mfumo wa taa za dharura wakati umeme wako kuu utazimwa. Na kwa kuwa una ujuzi hata kidogo katika vifaa vya elektroniki unapaswa kujua kwamba unaweza kuangalia kwa urahisi upatikanaji wa nguvu kuu kwa kupima th